Features

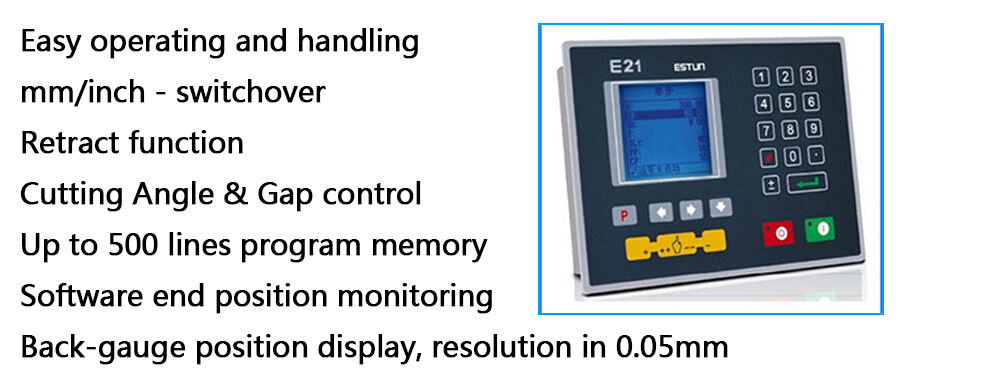

1.The 20mm shearing machine is constructed from high-quality steel plates, which are welded together to form a sturdy and durable structure. The hydraulic system is equipped with an accumulator return, ensuring smooth and reliable operation. The hydraulic system is also easy to operate, and the machine comes with a digital control system as a standard feature. This allows for precise and accurate cutting, making it an ideal choice for various industries.

2.The blade gap adjustment system is designed to be user-friendly and easy to operate. It is indicated by a signboard, which makes it easy to adjust the gap between the blades quickly and accurately. Additionally, the machine is equipped with light alignment devices and cutting stroke control devices, which ensure that the cutting process is convenient and fast. These features make it easy for operators to achieve accurate cuts with minimal effort.

3.The worktable is designed with rolling material support balls, which help reduce scratching on the sheet metal and frictional resistance. This ensures that the sheet metal remains in good condition during the cutting process, resulting in high-quality finished products. The support balls are also adjustable, allowing for customization based on the size and shape of the sheet metal being cut. The worktable is also designed to be easily removable, making it easy to clean and maintain.

Parameters

Parameters

| Mold | Cutting Thickness (mm) |

Cutting Length (mm) |

Angle Range (°) |

Backgauge Stroke (mm) |

Dimensions (mm×mm×mm) |

Main Motor (KW) |

| 6×2500 | 6 | 2500 | 1-3 | 750 | 3140×1740×2040 | 7.5 |

| 6×3200 | 6 | 3200 | 1-3 | 750 | 3750×1770×2150 | 7.5 |

| 6×4000 | 6 | 4000 | 1-3 | 750 | 4830×1840×2150 | 11 |

| 6×5000 | 6 | 5000 | 1-3 | 750 | 5830×1840×2150 | 11 |

| 6×6000 | 6 | 6000 | 1-3 | 750 | 6480×2100×2300 | 11 |

| 8×2500 | 8 | 2500 | 1-3 | 750 | 3040×1700×1700 | 11 |

| 8×3200 | 8 | 3200 | 1-3 | 750 | 3860×1700×1700 | 11 |

| 8×4000 | 8 | 4000 | 1-3 | 750 | 4640×1700×1700 | 11 |

| 8×5000 | 8 | 5000 | 1-3 | 750 | 5400×2400×2000 | 11 |

| 8×6000 | 8 | 6000 | 1-3 | 750 | 6480×2100×2350 | 11 |

| 8×8000 | 8 | 8000 | 1-3 | 750 | 8580×2130×2350 | 11 |

| 10×2500 | 10 | 2500 | 1-3 | 750 | 3040×1800×1700 | 15 |

| 10×3200 | 10 | 3200 | 1-3 | 750 | 3850×1830×1900 | 15 |

| 10×4000 | 10 | 4000 | 1-3 | 750 | 4650×2100×2000 | 15 |

| 10×5000 | 10 | 5000 | 1-3 | 750 | 5750×2100×2000 | 15 |

| 10×6000 | 10 | 6000 | 1-3 | 750 | 6500×2100×2300 | 15 |

| 10×8000 | 10 | 8000 | 1-3 | 750 | 8800×2100×2300 | 15 |

| 12×2500 | 12 | 2500 | 1-3 | 750 | 3285×1830×2390 | 15 |

| 12×3200 | 12 | 3200 | 1-3 | 750 | 3855×1830×2390 | 18.5 |

| 12×4000 | 12 | 4000 | 1-3 | 1000 | 4850×1830×2390 | 18.5 |

| 12×6000 | 12 | 6000 | 1-3 | 1000 | 6850×1930×2650 | 18.5 |

| 12×8000 | 12 | 8000 | 1-3 | 1000 | 8950×2130×2850 | 18.5 |

| 12×9000 | 12 | 9000 | 1-3 | 1000 | 9980×2300×2950 | 18.5 |

| 12×10000 | 12 | 10000 | 1-3 | 1000 | 11050×2500×3100 | 18.5 |

| 16×2500 | 16 | 2500 | 1-3 | 1000 | 3440×1940×2830 | 22 |

| 16×3200 | 16 | 3200 | 1-3 | 1000 | 4010×1940×2830 | 22 |

| 16×4000 | 16 | 4000 | 1-3 | 1000 | 5010×1980×2830 | 22 |

| 16×5000 | 16 | 5000 | 1-3 | 1000 | 5900×2600×2830 | 22 |

| 16×6000 | 16 | 6000 | 1-3 | 1000 | 6900×2700×2830 | 22 |

| 16×8000 | 16 | 8000 | 1-3 | 1000 | 8900×2900×3430 | 22 |

| 20×2500 | 20 | 2500 | 1-3 | 1000 | 3440×1900×2830 | 30 |

| 20×3200 | 20 | 3200 | 1-3 | 1000 | 4010×1900×2830 | 30 |

| 20×4000 | 20 | 4000 | 1-3 | 1000 | 4850×2600×2900 | 30 |

| 20×6000 | 20 | 6000 | 1-3 | 1000 | 6700×3000×3000 | 30 |

| 30×2500 | 30 | 2500 | 1-3 | 1000 | 3440×1900×2830 | 37 |

| 30×3200 | 30 | 3200 | 1-3 | 1000 | 4200×1900×3000 | 37 |

| 40×2500 | 40 | 2500 | 1-3 | 1000 | 3440×2000×3000 | 37 |

Packaging & Shipping

At Nadun Machinery, we take great care in ensuring that our products are delivered to our customers in the best condition possible. To achieve this, we use high-quality packaging materials that provide excellent protection against moisture and rust.

Our products are packaged internally with moisture-proof and anti-rust plastic materials, which are specifically designed to prevent damage during transit. These materials protect the machine from moisture and other environmental factors that could cause rust and corrosion

In addition to the internal packaging, we also use wooden packaging for external protection. The wooden packaging provides an extra layer of protection, ensuring that the machine is not damaged during transportation. This packaging is designed to absorb any impact or shock that may occur during transit, ensuring that the machine reaches its destination in perfect condition

To ensure that our customers receive their products in a timely and efficient manner, we offer exclusive container transportation services. This service is specifically designed for our customers, and it ensures that the products are delivered directly to their desired location. With our container transportation services, customers can rest assured that their products will be delivered safely and on time, regardless of their location.

Company profile

Nadun Machinery Manufacture Co., Ltd. specializes in manufacturing hydraulic presses, punch presses, shearing machines, bending machines, and other machinery that find wide applications in various industries such as automobile manufacturing, home appliances, and hardware processing

Our team of experienced professionals is committed to delivering excellence in their work. With a strong research and development team, we continuously innovate and upgrade our products to cater to the changing market demands. Our products are renowned for their superior quality, outstanding performance, and extended service life

At Nadun Machinery Manufacture Co., Ltd., we take immense pride in our dedication to providing exceptional products and services. Our stringent quality control procedures ensure that each product surpasses our customers' expectations. Furthermore, we provide tailored solutions to meet each customer's specific requirements

We understand that our success is intertwined with our customers' success. Hence, we strive to forge robust relationships with our customers, providing them with the necessary support and guidance to accomplish their objectives

If you're interested in learning more about our products or services, please don't hesitate to contact us. We eagerly anticipate the opportunity to collaborate with you and provide you with the most exceptional solutions for your needs.

FAQ

1.Could you furnish me with the relevant documentation?

Certainly, we are able to supply various documentation, including Certificates of Analysis/Conformance, insurance certificates, certificates of origin, and any other required export documents.

2.What's the typical lead time?

For samples, the lead time averages around 30 days. Regarding mass production, it usually takes 30-60 days after receipt of the deposit payment. Our lead times commence upon receipt of your deposit and your final product approval. If our lead times don't align with your timeline, please communicate your needs with your sales representative. In most instances, we can accommodate your requirements.

3.What payment methods are accepted?

We accept payment via bank transfers, Western Union, or PayPal. Our usual payment terms involve a 30% deposit upfront, followed by the remaining 70% balance against a copy of the Bill of Lading (B/L).

4.What kind of product warranty is provided?

We stand by the quality of our materials and workmanship. Our commitment centers on ensuring your satisfaction with our products. Whether within the warranty period or not, our company culture entails addressing and resolving all customer concerns to the contentment of all parties.

5.Can you guarantee the secure delivery of products?

Absolutely, we consistently employ high-quality export packaging methods to ensure the safe and secure delivery of our products. We also employ specialized hazard packaging for dangerous goods and validated cold storage containers for temperature-sensitive items. It's worth noting that specific or non-standard packing requirements may result in an additional charge.

6.How are shipping fees determined?

Shipping costs are contingent on the chosen method for receiving your goods. Express delivery is often the quickest albeit pricier option, while seafreight is preferable for larger quantities. We can furnish you with comprehensive freight rates once we have information regarding the quantity, weight, and shipping method. Kindly get in touch with us for further details.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy