The thin sheet metal forming and stretching hydraulic press is primarily used for metal thin sheet stretching, blanking, and punching processes. It also possesses the conventional functions of a general-purpose hydraulic press, making it widely applicable. When equipped with a hydraulic buffer, it can complete post-stretching punching or post-punching flanging processes. This equipment is widely used in various fields, including automotive, motorcycle, household appliances, petrochemical, rail transportation, aerospace, and aviation. This series of hydraulic presses is available in two structural forms: four-column and frame.

It can be configured according to user requirements with hydraulic pads, micro-adjustment mold devices, quick mold change devices, etc.

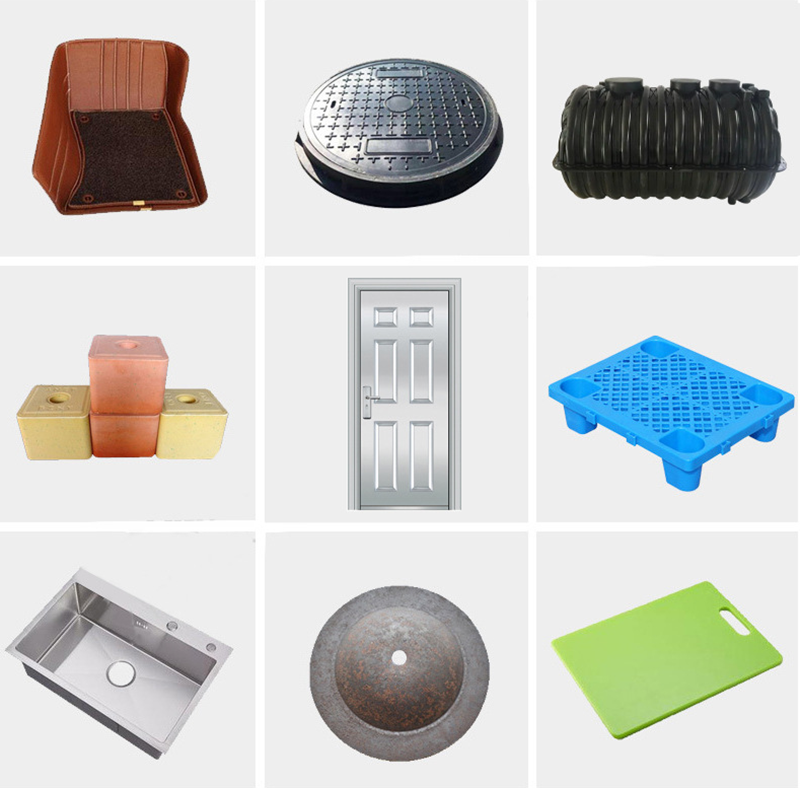

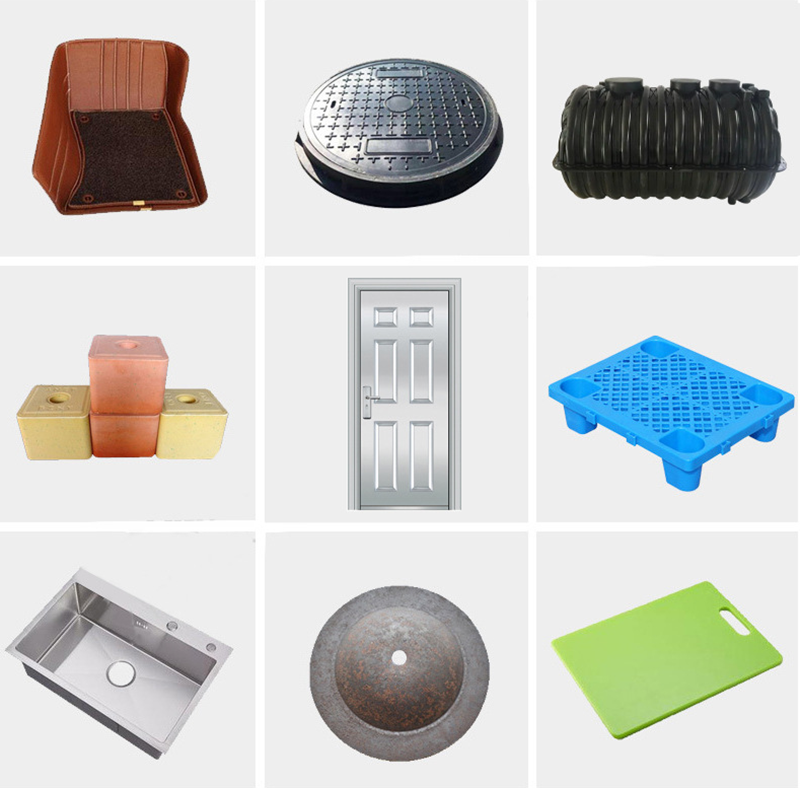

Part of the products that can be manufactured

The YD27 series sheet metal stretching and forming hydraulic press can be used to produce the products shown above.

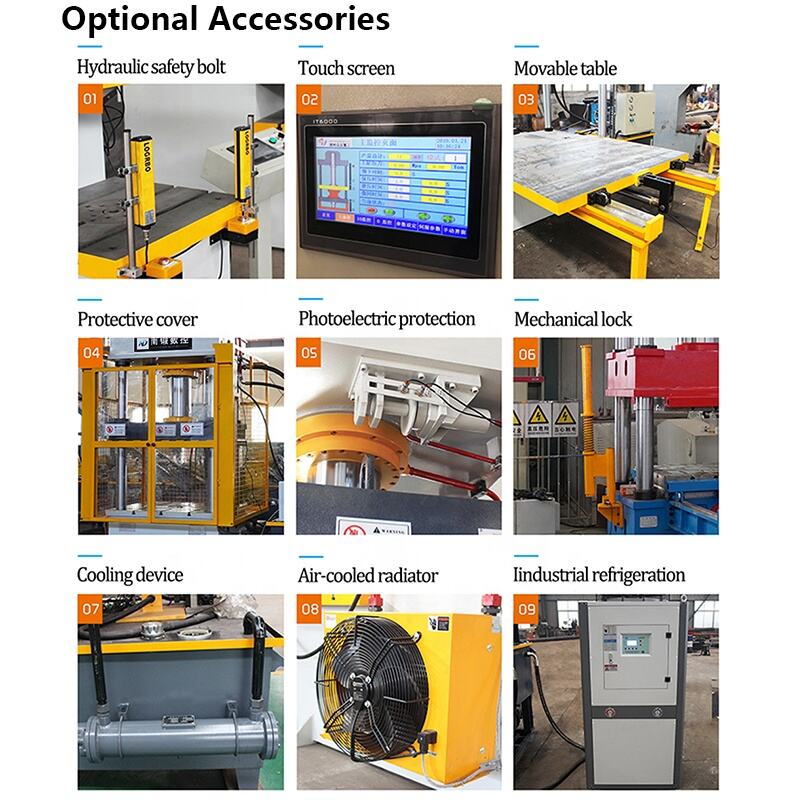

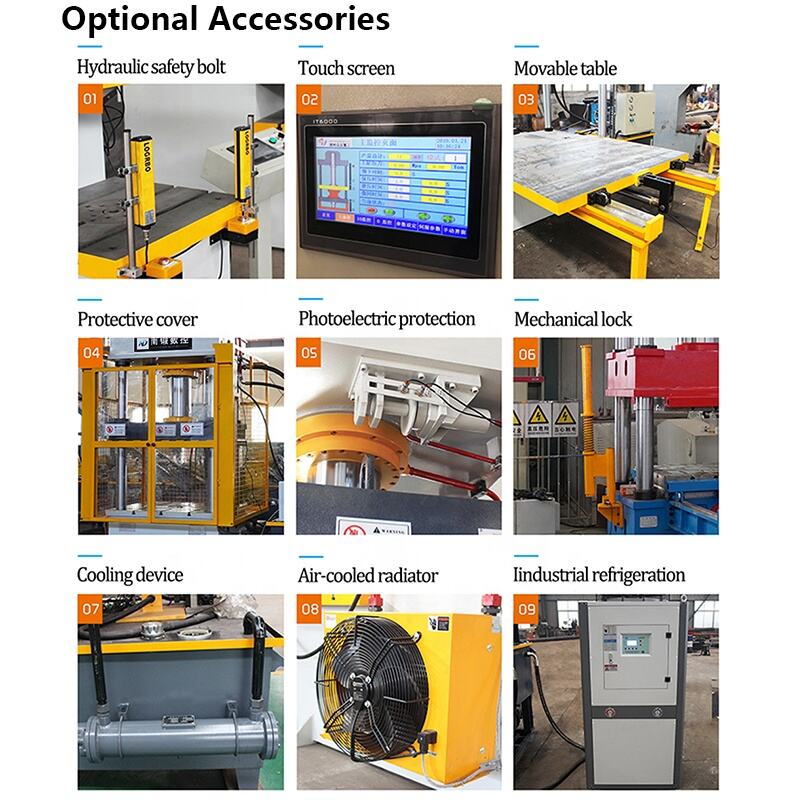

In addition to our standard models, our machines can be customized with various brands and types of components according to your specific requirements, achieving a high degree of customization.

Details Images

Main Piston Rod

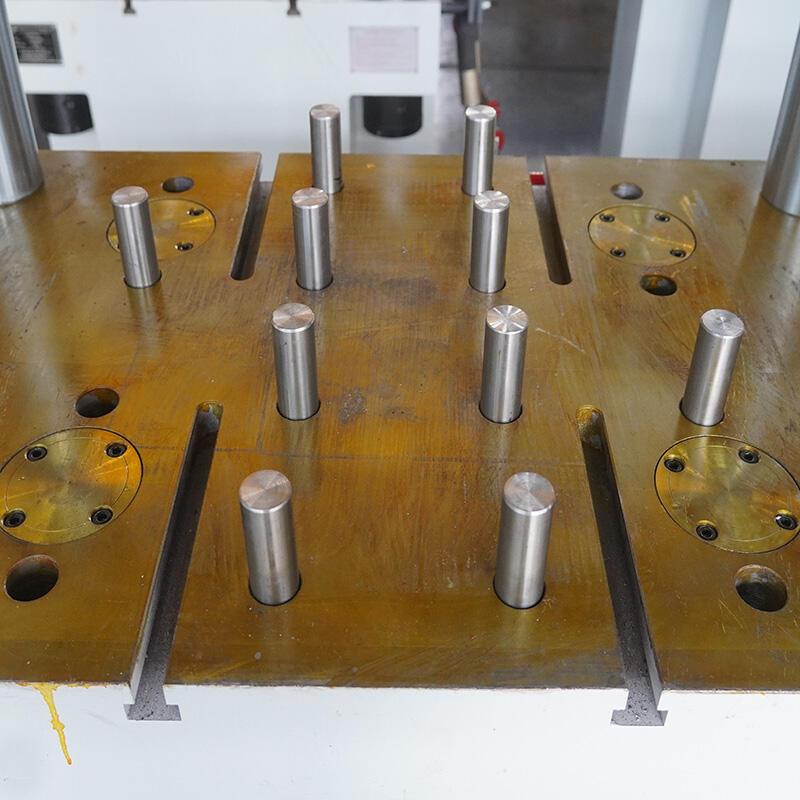

Slider and T-Slots and Multi-pole ejection

The electrical cabinet integrates hydraulic pressure gauges, adjustment knobs and temperature switch.

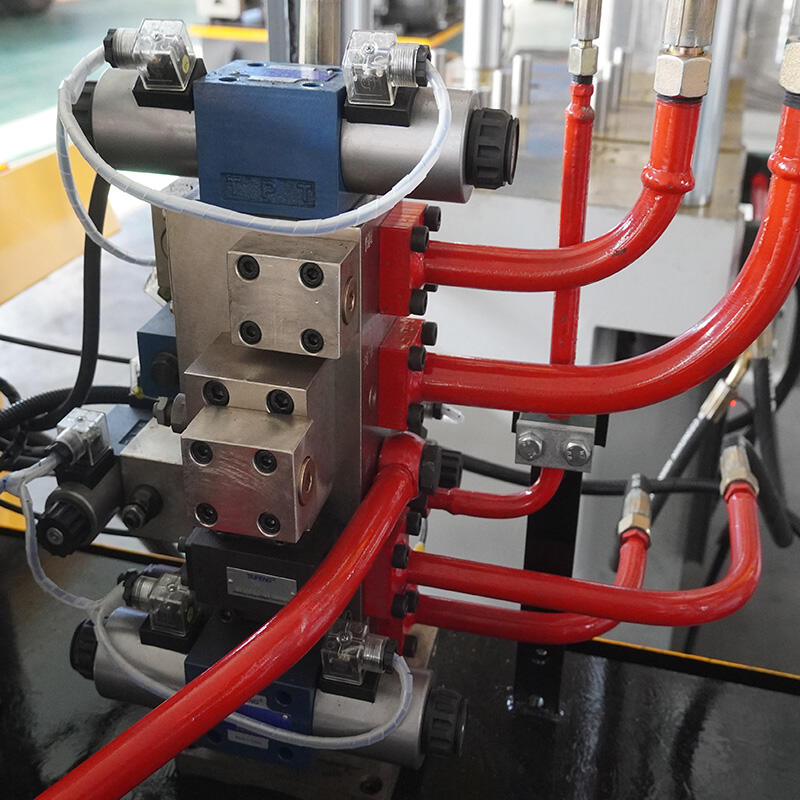

Independent Pump Station, Electrical Cabinet, and Mobile Control Console

Specification

|

item

|

value

|

|

Slide Stroke (mm)

|

600

|

|

Machine Type

|

Four-column Three-beam Hydraulic Press

|

|

Ejector Force (kN)

|

500

|

|

Return Force (kN)

|

300kN

|

|

System

|

Normal

|

|

Condition

|

New

|

|

Place of Origin

|

China

|

|

Brand Name

|

Nadun

|

|

Year

|

2024

|

|

Voltage

|

380V/Optional

|

|

Weight (T)

|

3.4T

|

|

Model Number

|

YD27-100T

|

|

Motor Power (kw)

|

7.5kw

|

|

Key Selling Points

|

Competitive Price

|

|

Warranty

|

1 Year

|

|

Applicable Industries

|

Building Material Shops, Garment Shops, Machinery Repair Shops, Manufacturing Plant, Energy & Mining, Construction works

|

|

Showroom Location

|

None

|

|

Marketing Type

|

Ordinary Product

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

Bearing, Motor, Pump, Pressure vessel

|

|

Hydraulic Pressure

|

25 Mpa

|

|

Opening Height

|

900 mm

|

|

Effective Table Area

|

750*700 mm

|

|

Down Speed

|

90 mm/s

|

|

Pressing Speed

|

17 mm/s

|

|

Return Speed

|

110 mm/s

|

|

Hydraulic Cushion Ejection Force

|

500 KN

|

|

Ejection Stroke

|

300 mm

|

|

Hydraulic Cushion Area

|

750*700 mm

|

Product Paramenters

|

SPECIFICATION

|

UNIT

|

100T

|

200TA

|

200TB

|

315T

|

500T

|

|

Max. System pressure

|

Mpa

|

25

|

25

|

25

|

25

|

25

|

|

Max. Stroke of sliderOpening

|

mm

|

600

|

600

|

700

|

800

|

900

|

|

Max. Open height

|

mm

|

900

|

900

|

1200

|

1250

|

1500

|

|

Effective table size

|

mm

|

750x 700

|

800x800

|

1000x1000

|

1260x1160

|

1400x1400

|

|

Down speed

|

mm/s

|

90

|

100

|

100

|

120

|

120

|

|

Pressing speed

|

mm/s

|

17

|

14

|

14

|

11

|

18

|

|

Return speed

|

mm/s

|

110

|

110

|

110

|

100

|

170

|

|

Motor power

|

KW

|

7.5

|

7.5

|

7.5

|

22

|

22*2

|

|

Hydraulic cushion force

|

T

|

50

|

60

|

60

|

100

|

160

|

|

Cushion stroke

|

mm

|

300

|

300

|

300

|

300

|

300

|

The aforementioned table details the standard specifications for our YD27 series of deep drawing hydraulic presses, with the 100-ton model being the emphasized variant. Additionally, we are capable of tailoring machinery to meet diverse types and applications as per your specific needs.

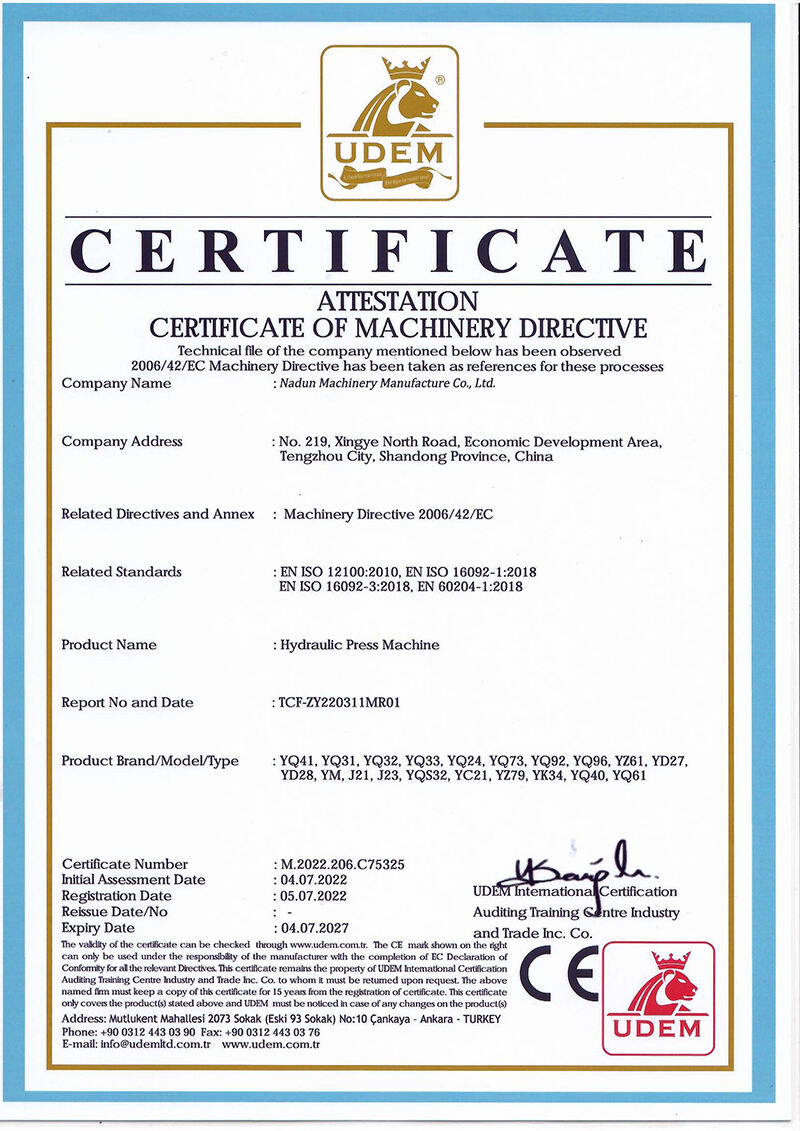

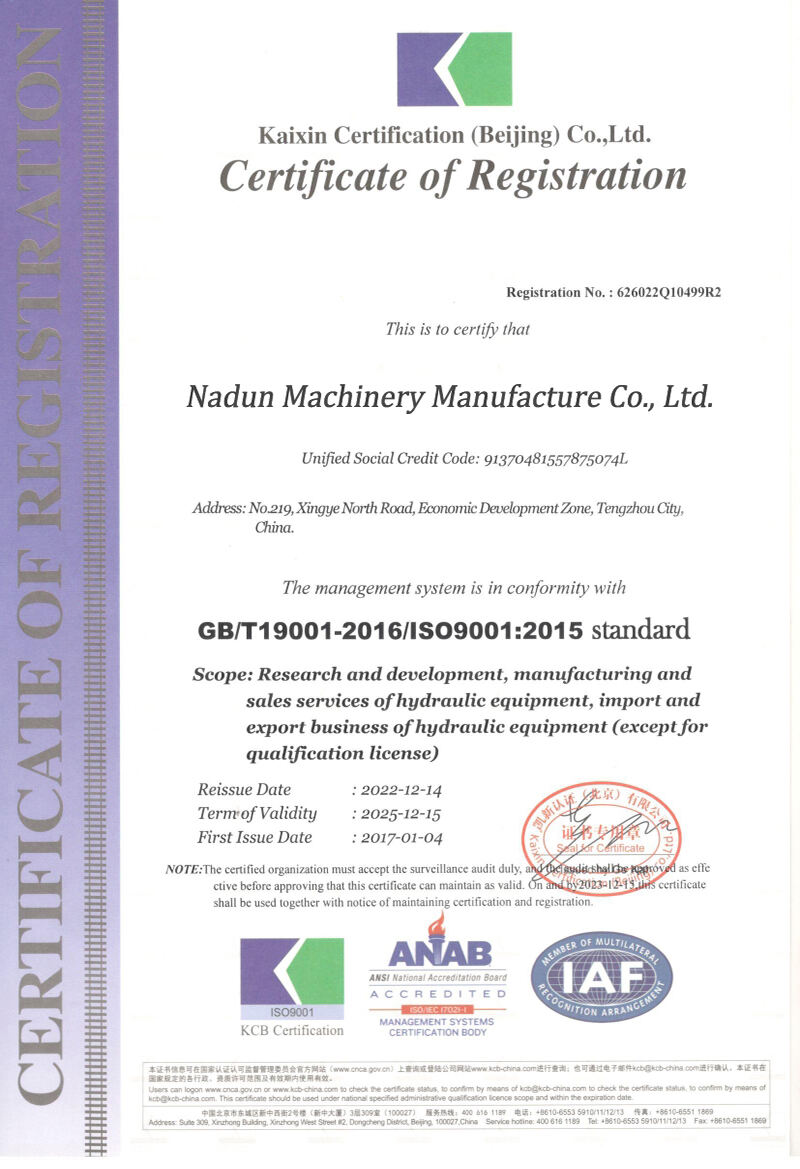

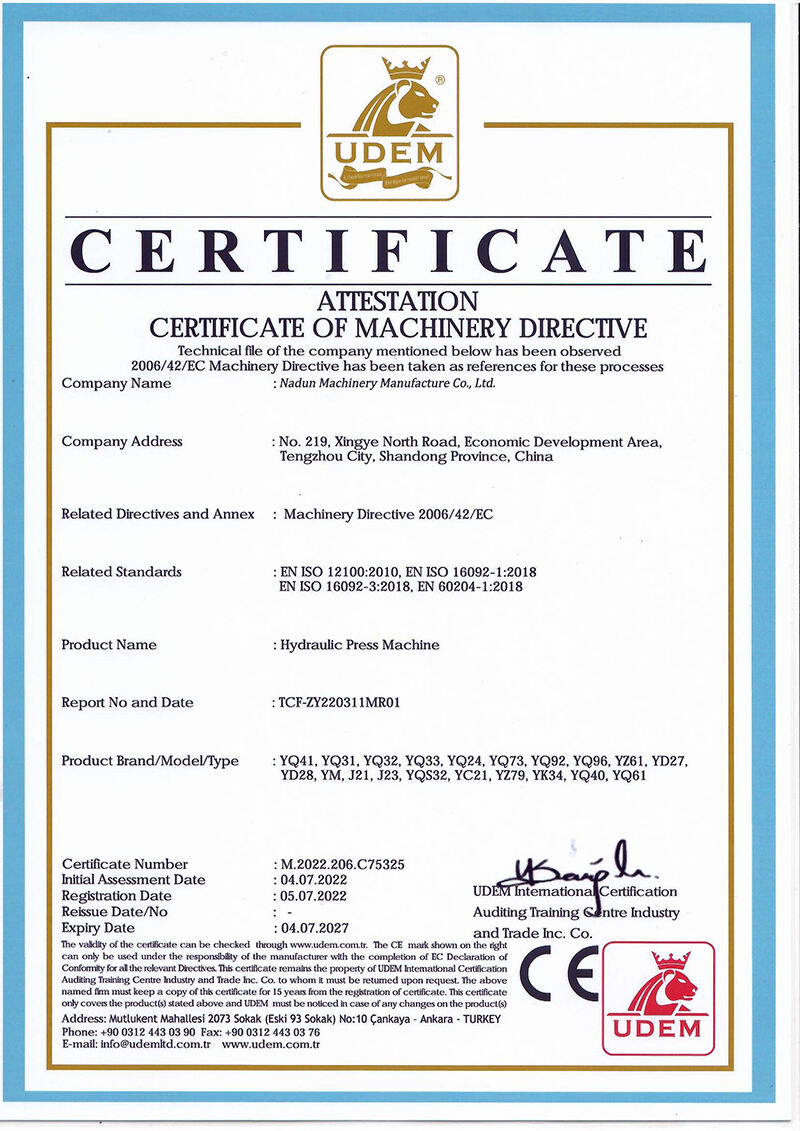

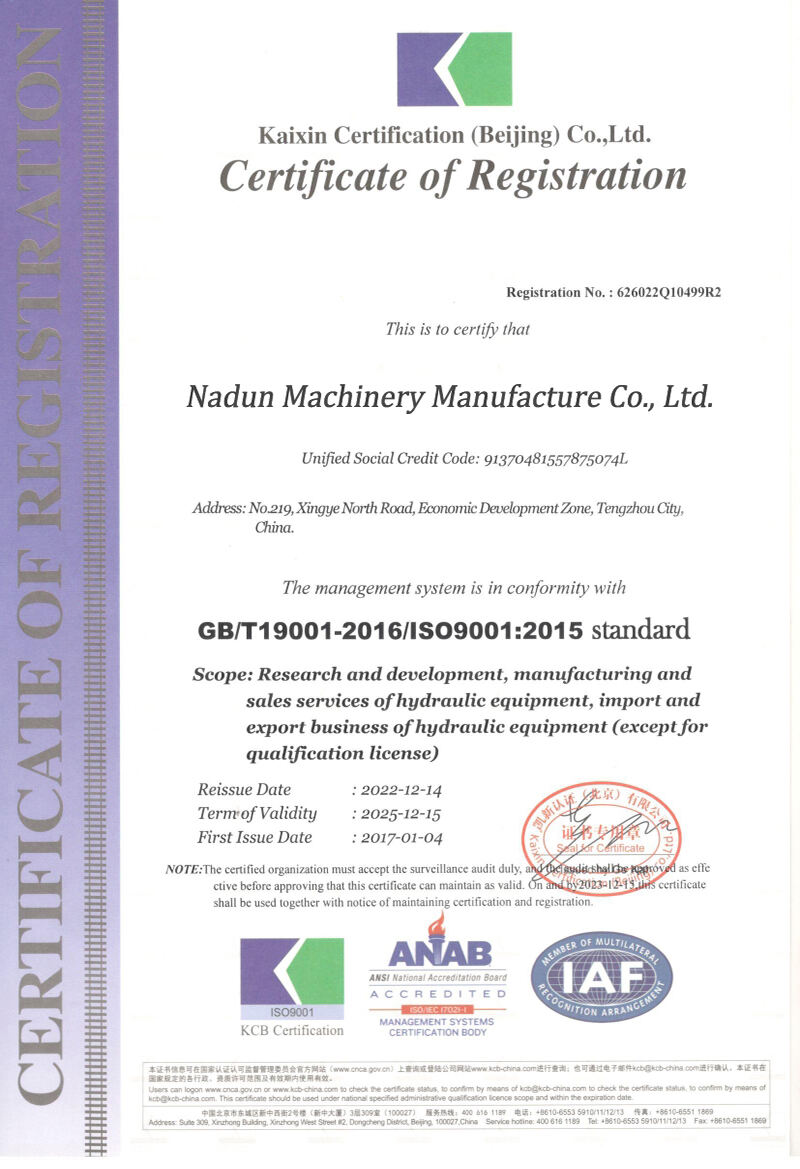

Certifications

CE Certification

ISO 9001 Certification

Customer Visit

Partner