The four-column general-purpose hydraulic press adopts a three-beam and four-column structure for its body. The hydraulic system uses cartridge valve integrated control and is equipped with an independent and reliable electrical control system. It has broad versatility, making it suitable for the pressing and forming of various plastic materials, such as extrusion, bending, flanging, and drawing. It can also be used for the pressing and forming of various plastic and powder products.

It can achieve two forming processes: fixed stroke and fixed pressure, and it also has features such as pressure-holding delay. This makes it widely applicable and economically advantageous.

If the hydraulic press is used for blanking or punching processes, a punching buffer device should be installed to eliminate or reduce the impact and noise at the moment the material is sheared.

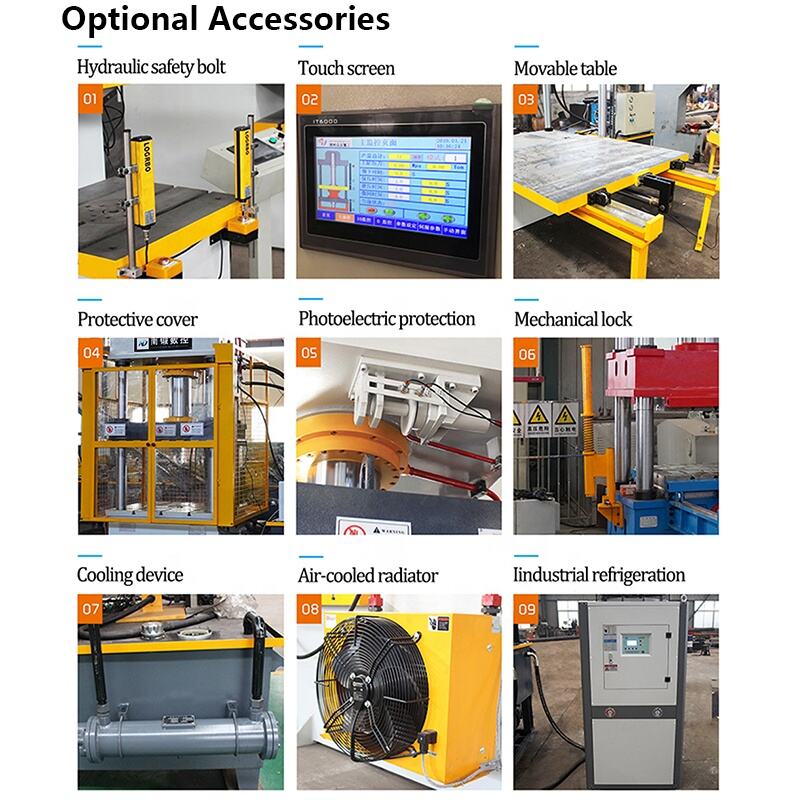

High customization capabilities

Each part of our machines features components from different brands and a variety of types for you to choose from. Our machines offer extremely high customization capabilities, allowing you to tailor the functions and brands used according to your requirements.

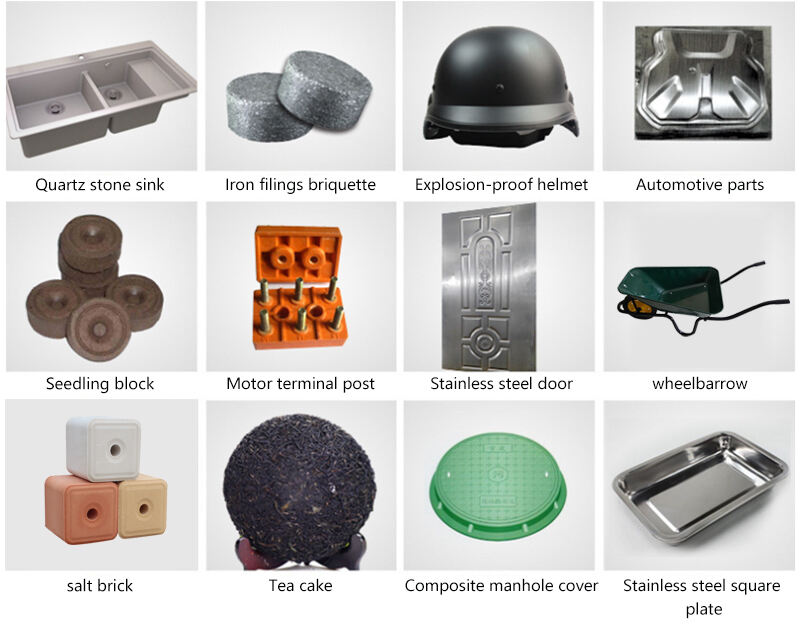

Versatile Uses

Our machines are generally multi-functional, capable of producing various types of products by using different molds. The image above shows some of the products that can be produced by our YQ32-200T four-column hydraulic press. Our machines are equipped with T-slots on the workbench and slide block, facilitating easy mold updates and quick replacements.

Details Images

Specification

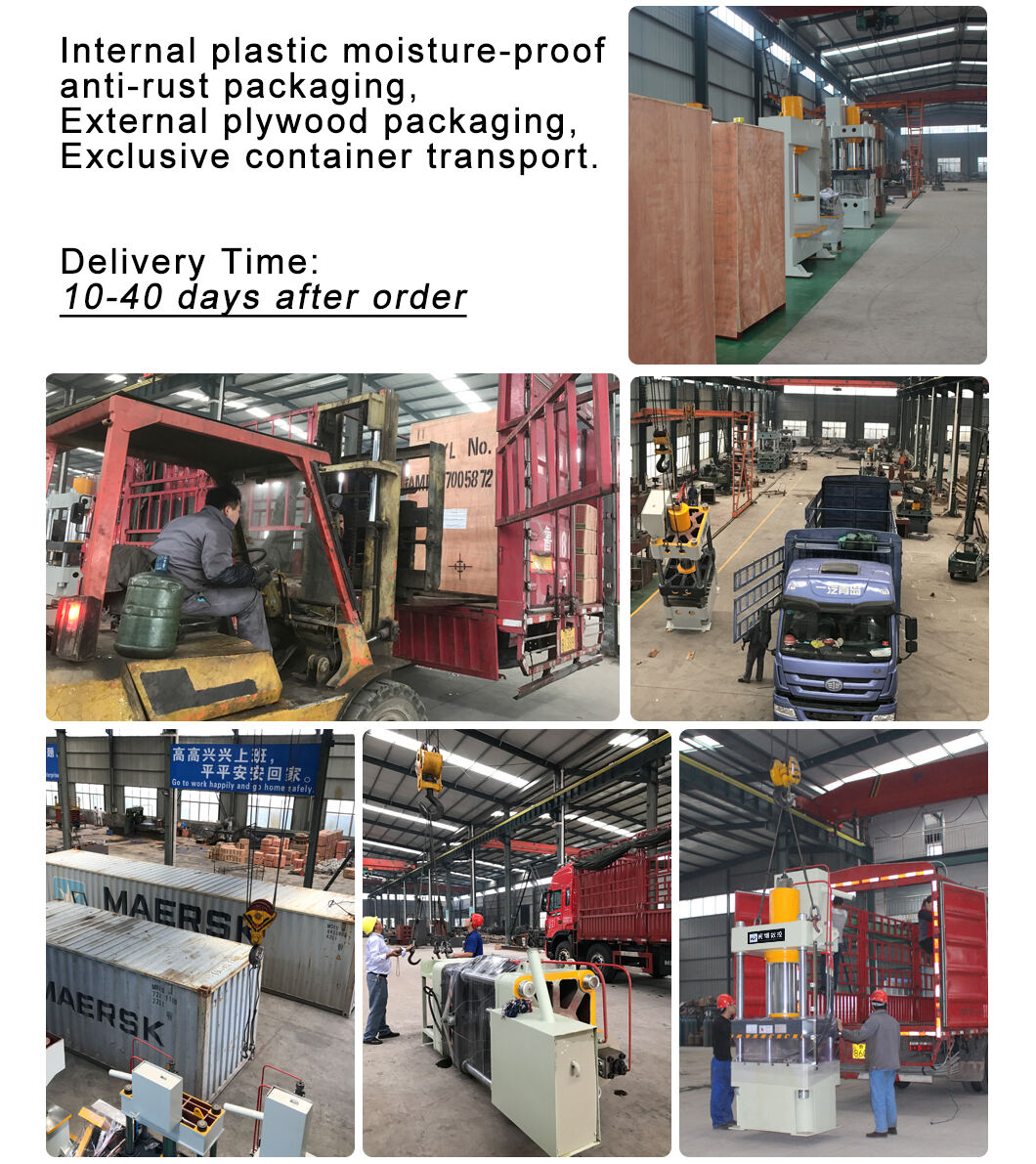

Packing & Delivery

Delivery Time:10-40 days after order.

Internal plastic moisture-proof anti-rust packaging,External plywood packaging,Exclusive container transport.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy