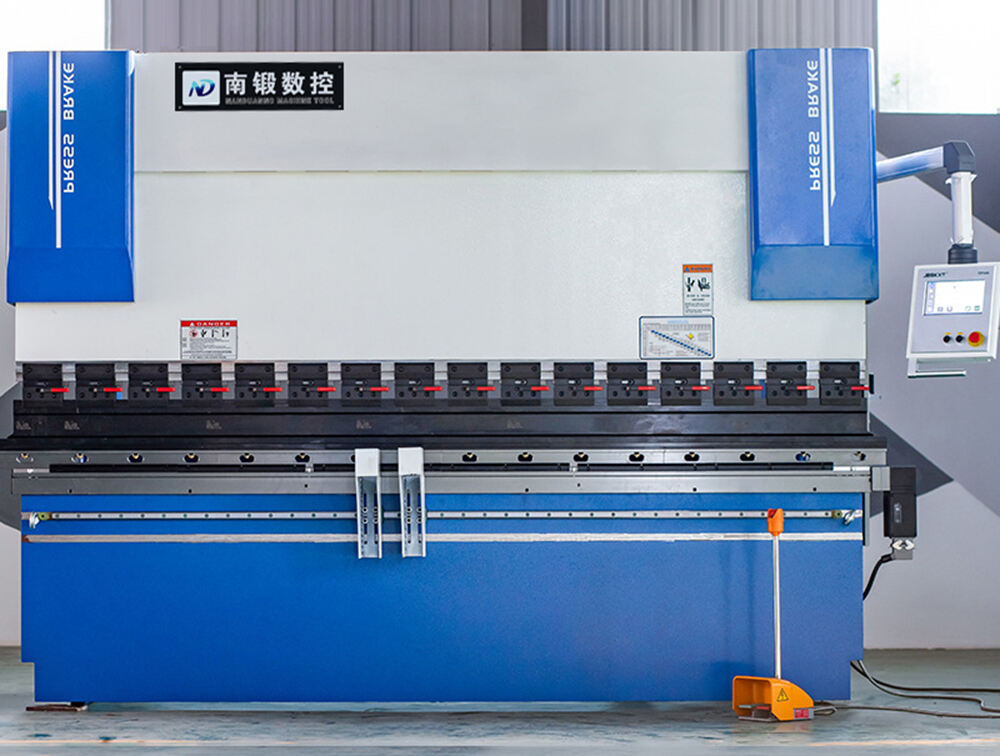

The bending machine is a machine that can bend thin plates. Its structure mainly includes a bracket, a workbench and a clamping plate. The workbench is placed on the bracket. The workbench consists of a base and a pressure plate. The base is connected to the clamping plate through a hinge. The base consists of a base shell, a coil and a cover plate. The coil is placed in the depression of the base shell, and the top of the depression is covered with a cover plate. When in use, the coil is energized by a wire, and after energization, a gravitational force is generated on the pressure plate, thereby clamping the thin plate between the pressure plate and the base. Due to the use of electromagnetic force clamping, the pressure plate can be made into a variety of workpiece requirements, and can process workpieces with side walls, which is easy to operate.

Features

Packaging & Shipping

We are committed to safeguarding our products with a robust packaging and transportation strategy. Internally, we use moisture-resistant plastic packaging with anti-rust properties to protect items from environmental factors that could affect quality. Externally, our products are encased in sturdy wooden packaging for added security during shipping. We also employ specialized container transport methods to enhance safety. This careful approach to packaging and transportation reflects our unwavering dedication to delivering high-quality products to our valued customers.

Company Profile

Nadun Machinery Manufacture Co., Ltd. is a company specializing in the production of hydraulic presses, punch presses, shearing machines, bending machines, and other machinery. Our products are widely used in various industries such as automobile manufacturing, home appliances, and hardware processing.

Our company has a team of experienced professionals who consistently strive for excellence in their work. We have a strong research and development team that constantly innovates and improves our products to meet the ever-changing market demands. Our products are known for their high quality, excellent performance, and long service life.

At Nadun Machinery Manufacture Co., Ltd., we take pride in our commitment to providing customers with exceptional products and services. We have strict quality control procedures in place to ensure that each product meets or exceeds our customers' expectations. Furthermore, we offer customized solutions to meet specific customer requirements.

We believe that our success is closely tied to the success of our customers. For this reason, we work hard to build strong relationships with our customers and offer them the support and guidance they need to achieve their goals.

If you are interested in learning more about our products or services, please do not hesitate to contact us. We look forward to the opportunity to work with you and provide you with the best solutions for your needs.

FAQ

1.Can you provide me with the relevant documentation?

Yes, we can provide you with most documentation including Certificates of Analysis/Conformance, insurance, origin, and other export documents where required.

2.What is the average lead time?

For samples, the lead time is about 30 days. For mass production, the lead time is 30-60 days after receiving the deposit payment. Our lead times become effective when we have received your deposit and have your final approval for your products. If our lead times do not work with your deadline, please discuss your requirements with your sales representative. In most cases, we are able to accommodate your needs.

3.What payment methods do you accept?

We accept payment via bank transfer, Western Union, or PayPal. The payment terms are typically a 30% deposit in advance, with the remaining 70% balance due against the copy of B/L.

4.What is the product warranty?

We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. Whether in warranty or not, it is our company culture to address and resolve all customer issues to everyone's satisfaction.

5.Do you guarantee safe and secure delivery of products?

Yes, we always use high-quality export packaging to ensure the safe and secure delivery of our products. We also use specialized hazard packing for dangerous goods and validated cold storage shippers for temperature-sensitive items. However, specialist packaging or non-standard packing requirements may incur an additional charge.

6.How about the shipping fees?

The shipping cost depends on the method you choose to receive your goods. Express delivery is usually the quickest but also the most expensive option. Sea freight is the best solution for large amounts. We can provide you with detailed freight rates once we know the details of the amount, weight, and shipping method. Please contact us for further information.

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy