Product Preview

1.The base, columns, and slide are made of high-grade gray cast iron and are tempered to ensure the machine tool has high strength and long-term precision stability.

2.The machine tool uses roller-type linear guides, which have ultra-high rigidity and heavy load capacity. This greatly enhances the positioning accuracy and load-bearing capacity of the machine tool's longitudinal and transverse feed movements.

3.The servo main motor is connected to the spindle through a synchronous toothed belt, ensuring repeat positioning accuracy of the workpiece. It offers stepless speed variation, and the wide speed range can meet the different spindle speed requirements for difficult and fine machining of various parts.

4.The longitudinal and transverse feeds are controlled by high-power servo motors for automatic feeding. The longitudinal feed is equipped with a load balancing mechanism, effectively reducing the load on the lead screw and greatly extending its service life.

5.Both ends of the longitudinal and transverse ball screws of the machine tool are supported by imported double-row bearings, which greatly improve and ensure the machining accuracy of parts.

6.The machine tool uses an adjustable electric lubrication oil pump for intermittent automatic lubrication of various parts, ensuring the lubrication of all guide rails and lead screws, and guaranteeing the operating precision of each moving part.

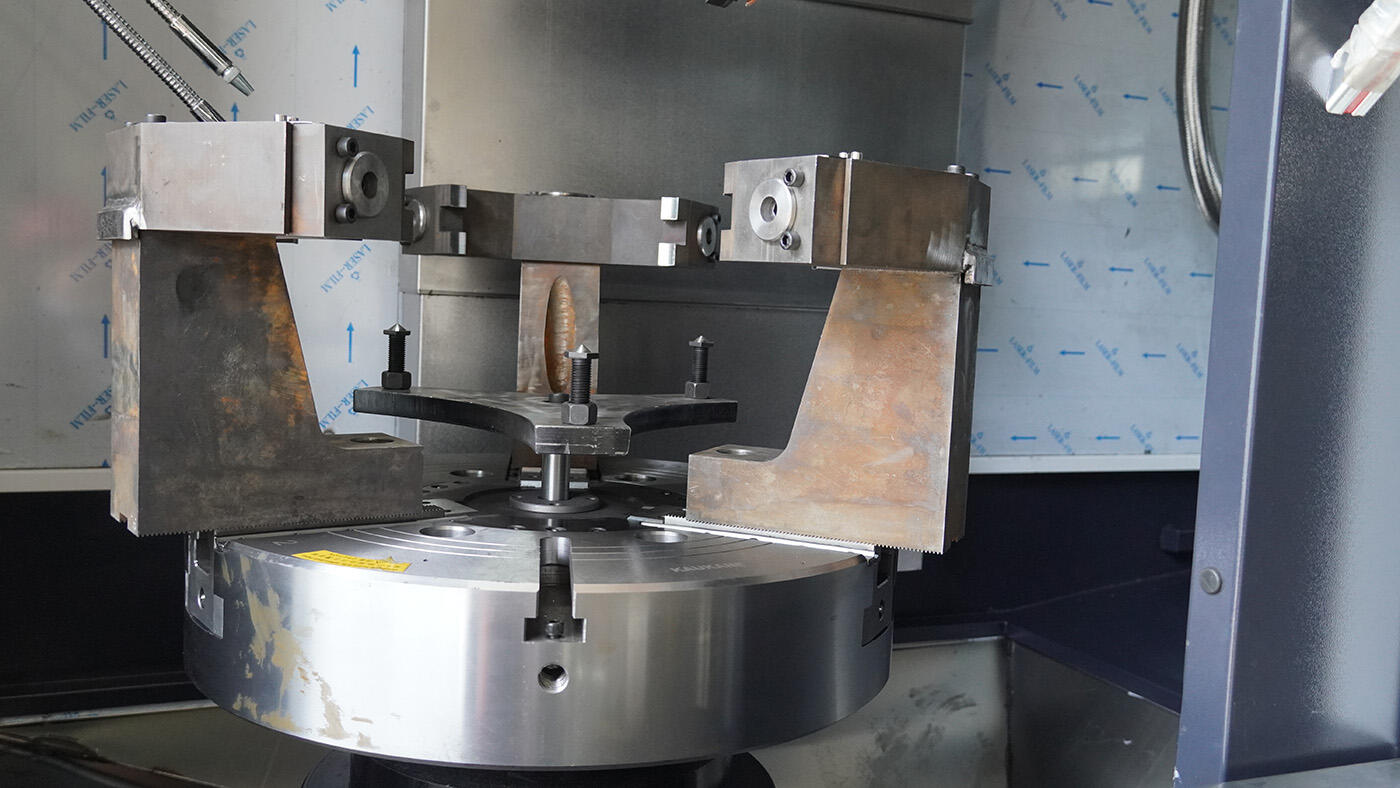

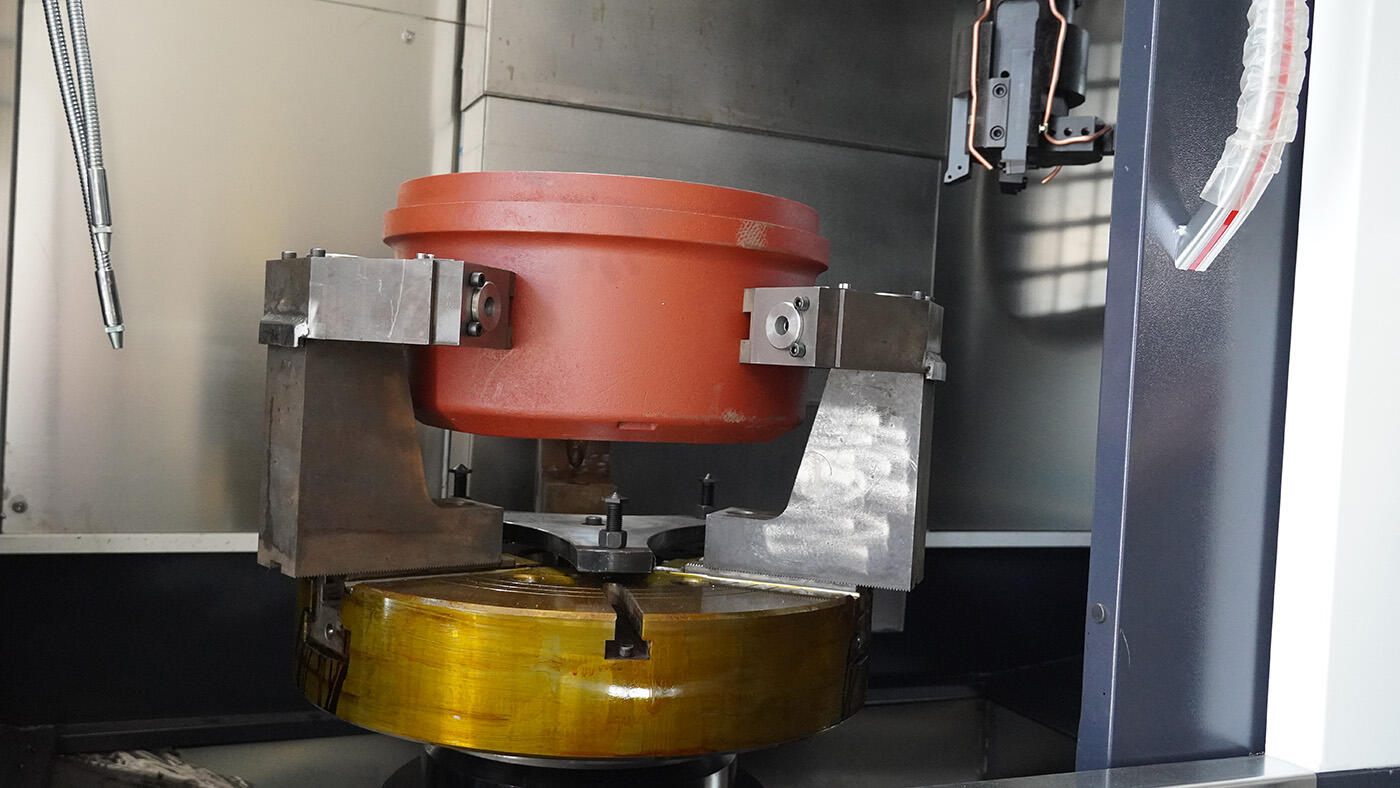

7.The tool post of the machine tool adopts a horizontal or vertical multi-station CNC tool post for one-time clamping of tools. The short tool change time greatly improves work efficiency.

8.The upper end of the spindle can be equipped with a disc-type worktable or hydraulic chuck according to user requirements. The lower end of the spindle can be equipped with a rotary cylinder, which is available in single-piston and double-piston types. The single-piston cylinder can be used to control the fixture to clamp the workpiece or control the hydraulic chuck. The double-piston cylinder has one cylinder controlling the hydraulic chuck, while the other cylinder controls the fixture to clamp the workpiece.

Product Details

Product Specifications

| Project | Specification | Unit | VT45 | VT65 | VT75 |

| Machining Capacity | Max. Turning Diameter | mm | ∮560 | ∮650 | ∮750 |

| Max. Cutting Diameter | mm | ∮450 | ∮600 | ∮700 | |

| Spindle | Spindle Face Type | Straight | Straight | Straight | |

| Spindle Speed | rpm | 100-2000 | 100-1000 | 100-1000 | |

| Chuck Diameter | mm | 500 | 500 | 610 | |

| Tool Magazine | Tool Capacity | pc | Horizontal 8 | Horizontal 8 | Horizontal 8 |

| Travel | X-Axis Travel | mm | 400 | 420 | 700 |

| Z-Axis Travel | mm | 500 | 500 | 700 | |

| Hydraulic Unit | Oil Tank Capacity | L | 40 | 40 | 40 |

| Hydraulic Motor Power | kW | 2 | 2 | 2 | |

| Motor | Spindle Servo Motor Power | kW | 15 | 19 | 22 |

| Accuracy | Repeated Positioning | mm | ±0.008 | ±0.005 | ±0.005 |

| Positioning Accuracy | mm | ±0.008 | ±0.008 | ±0.008 | |

| Machine Dimensions | Length * Width * Height | mm | 2200*2300*2600 | 2150*2210*2970 | 2700*2100*3200 |

| Weight (with Accessories) | kg | 5000 | 7000 | 9500 | |

| Power Requirements | Power Supply | 3¢-AC 380V 50HZ±5% | |||

| Leakage protection, power failure protection | √ | ||||

| Three-color indicator for machine status | √ | ||||

| Long-term stable operation under the following conditions | Ambient temperature 5~38° | ||||

| Ambient humidity<85% | |||||

| Machine noise meets national standards | √ | ||||

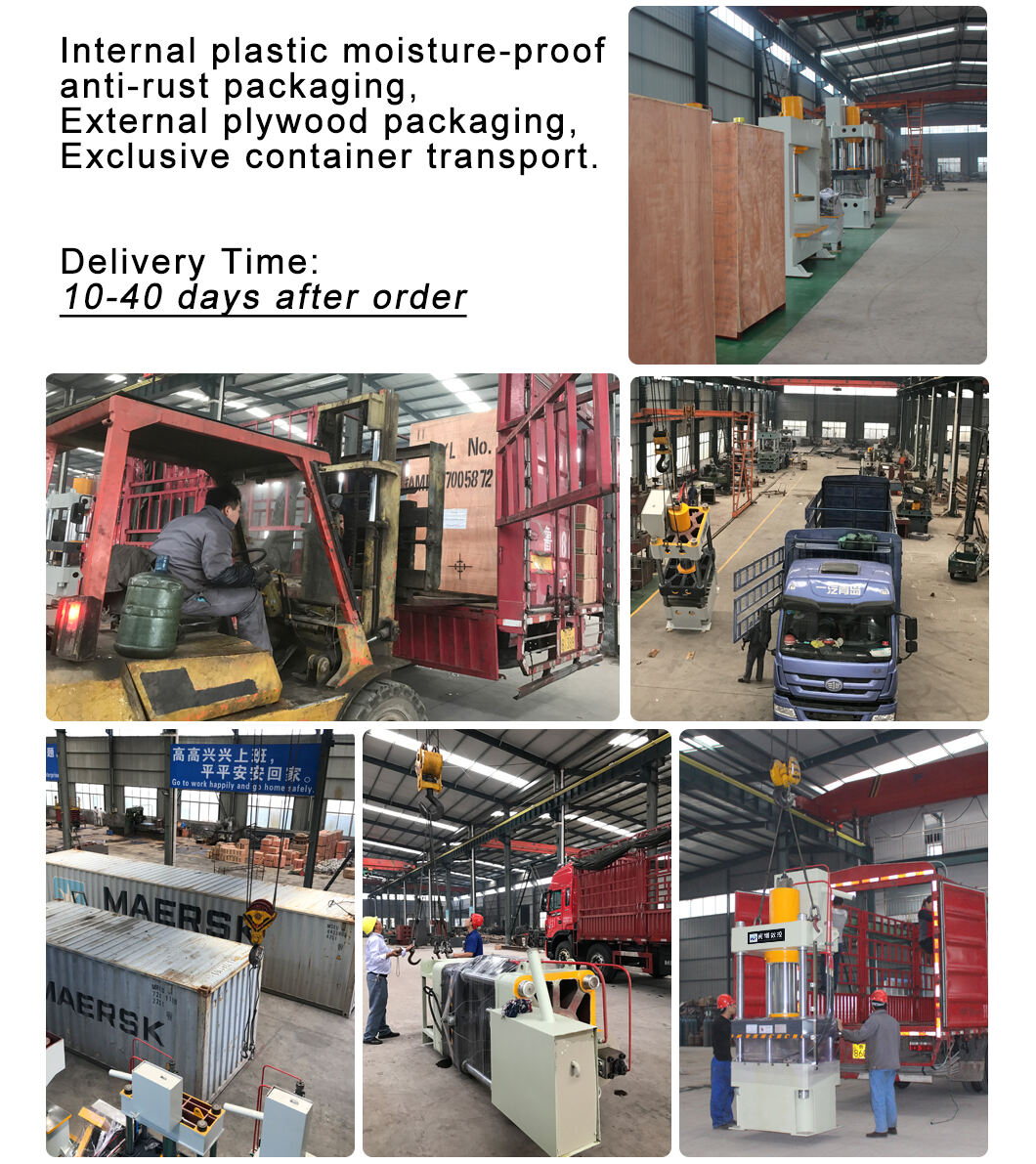

Product Packaging

Customer Visit

Our friendly team would love to hear from you!

Copyright © Nadun Machinery Manufacture Co.,Ltd. All Rights Reserved - Privacy Policy