The Principles and Application Scenarios of CNC Vertical Lathes

CNC Vertical Lathes: The Precision "Craftsmen" of Industrial Manufacturing

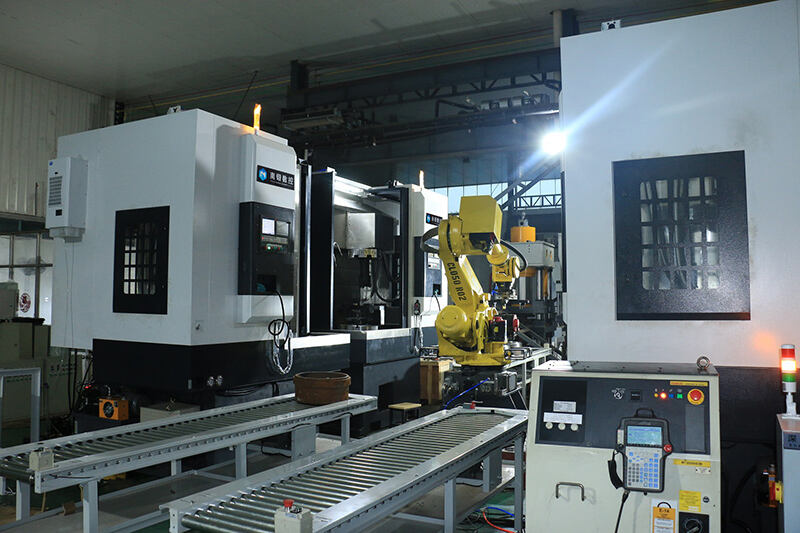

In the field of precision machining in modern manufacturing, CNC vertical lathes play an irreplaceable and crucial role. They are key equipment for achieving high - precision and high - efficiency production in numerous industrial sectors. Next, let's delve into the working secrets of CNC vertical lathes and their extensive application scenarios.

I. Working Principle: A Precise Co - operating System

A CNC vertical lathe is a complex system integrating advanced technology and precision machinery, mainly composed of three core parts: the CNC system, the mechanical structure, and the servo drive.

1.The CNC System: The Precise "Intelligent Brain"

The CNC system, as the central nervous system of the CNC vertical lathe, is like a sophisticated computer. According to the pre - written and input machining programs, it analyzes and calculates various complex machining instructions. It precisely controls every movement of the machine tool, enabling control with millimeter - level accuracy in aspects such as the direction of movement, speed, and displacement distance, ensuring high - precision and stability during the machining process.

2.The Mechanical Structure: The Solid Foundation for Machining

The mechanical structure serves as the physical support of the CNC vertical lathe. Components such as the spindle, worktable, and tool holder cooperate closely to complete the machining tasks. The thick and high - precision spindle is responsible for driving the workpiece to rotate at high speed, providing the power required for cutting. The sturdy and stable casting worktable bears the workpiece, ensuring its stability during the machining process. The flexible tool holder can install various types of cutting tools and accurately position the tools to the designated positions according to machining requirements, creating conditions for cutting.

3.The Servo Drive: The Bridge between Instructions and Movements

The servo drive system is like an efficient executor. It receives the command signals sent by the CNC system and converts these signals into precise mechanical movements. Through precise control of the motor, the servo drive can achieve rapid and smooth movement of components such as the worktable and tool holder, as well as accurate position positioning. This ensures that the relative movement between the cutting tool and the workpiece can be carried out strictly in accordance with the programming requirements, providing a strong guarantee for machining high - quality parts.

4.Cutting Machining: Giving the Part Its Final Form

During the machining process of the CNC vertical lathe, the cutting movement between the cutting tool and the workpiece is a key link in achieving part machining. Under the coordinated control of the CNC system and the servo drive, the sharp cutting tool cuts the high - speed rotating workpiece with precise trajectories and parameters. By removing excess material, the workpiece is gradually shaped into the shape and size that meet the design requirements, endowing the part with its final practical value and industrial aesthetics.

II. Application Scenarios: Widely Covered and Indispensable

With their high - precision, high - efficiency, and high - flexibility machining characteristics, CNC vertical lathes play a pivotal role in many industrial fields.

1.Aerospace Field: Facilitating Cutting - edge Manufacturing

The aerospace industry has extremely high requirements for the precision and quality of components. CNC vertical lathes can shoulder the important task of machining key components such as engine blades and aircraft structural parts. These components not only have complex shapes but also have almost stringent requirements for dimensional accuracy and surface quality. Through their excellent machining performance, CNC vertical lathes can ensure that each part meets the design standards, providing a solid guarantee for the safe flight and high - performance operation of aerospace vehicles.

2.Automotive Manufacturing Industry: Promoting Efficient Production

In the process of automotive manufacturing, CNC vertical lathes are widely used in the machining of components such as engine blocks and wheels. As the core component of the "heart" of the car, the machining accuracy of the engine block directly affects the performance and reliability of the engine. Wheels need to have good dynamic balance performance and accurate dimensional accuracy to ensure the safety and comfort of the car during driving. CNC vertical lathes can quickly and accurately complete the machining of these components, greatly improving the efficiency and quality of automotive production and promoting the development of the automotive manufacturing industry towards high - efficiency and precision.

3.Energy Equipment Manufacturing: Meeting the Needs of Large - scale Components

With the continuous development of the energy industry, the demand for large - scale energy equipment such as wind power equipment and nuclear power equipment is increasing. The large - scale components of these equipment usually have huge sizes, astonishing weights, and extremely high requirements for machining accuracy and quality. Relying on their strong load - bearing capacity and high - precision machining performance, CNC vertical lathes can easily meet the machining challenges of these large - scale components, such as the tower flange of wind power equipment and the reactor pressure vessel of nuclear power equipment, providing key technical support for the manufacturing of energy equipment.

4.General Machinery Manufacturing: A Capable Assistant for Basic Machining

In the field of general machinery manufacturing, CNC vertical lathes are also indispensable machining equipment. They are widely used in the machining of various general mechanical parts, such as shaft parts and disk parts. Although these parts have relatively simple structures, they account for a large proportion in the mechanical manufacturing industry in terms of quantity. With their efficient and stable machining performance, CNC vertical lathes can quickly complete the machining of a large number of parts, meeting the dual needs of the general machinery manufacturing industry for production efficiency and product quality.

III. Choose Our CNC Vertical Lathes: Double Guarantee of Quality and Service

As a professional manufacturer of CNC vertical lathes, we are committed to providing customers with high - quality products and comprehensive high - quality services.

1.Excellent Quality: Setting an Industry Example

We always adhere to quality as the core. In the production process of CNC vertical lathes, we select high - quality raw materials and adopt advanced manufacturing processes. From the machining of components to the assembly of the whole machine, every link strictly follows international standards and industry specifications. After multiple quality inspection procedures, we ensure that each CNC vertical lathe leaving the factory has excellent stability and durability, can maintain excellent performance during long - term high - intensity work, and create greater value for customers.

2.Advanced Technology: Leading the Industry Trend

We continuously increase investment in technology research and development and actively introduce advanced domestic and foreign CNC technologies and manufacturing concepts. Our CNC vertical lathes are equipped with advanced high - precision control systems and have intelligent machining functions such as automatic tool setting, tool compensation, and fault diagnosis, enabling more complex and efficient machining tasks. At the same time, we also focus on product customization, providing customized solutions according to the different needs of customers to meet their diverse production requirements.

3.Professional Service: All - round Attentive Care

We are well aware that high - quality service is one of the important factors for customers to choose us. Therefore, we have established a professional and efficient service team to provide customers with all - round pre - sales, in - sales, and after - sales services. In the pre - sales stage, our technical experts will communicate in depth with customers to understand their production needs and process requirements, and provide professional technical consultation and equipment selection suggestions. In the in - sales stage, we will strictly complete the production and delivery of equipment on time, in accordance with quality and quantity as agreed in the contract, and provide customers with equipment installation and commissioning services to ensure that the equipment can be put into use smoothly. In the after - sales stage, we will provide customers with timely and efficient technical support and maintenance services, regularly visit customers to understand the use of the equipment, and promptly solve the problems encountered by customers during the use process, leaving customers with no worries.

IV. Conclusion: Looking Ahead, Continuous Innovation

As important equipment in modern industrial manufacturing, CNC vertical lathes play an irreplaceable role in promoting the development of various industries. They not only improve production efficiency and product quality but also make it possible to machine complex components, driving the continuous progress of industrial manufacturing technology. With the rapid development of science and technology, CNC vertical lathe technology will also continue to innovate and upgrade, moving towards higher precision, higher efficiency, and more intelligent directions. We believe that in the future industrial manufacturing field, Nadun CNC vertical lathes will continue to play an important role and make greater contributions to the development of the global manufacturing industry. And we will always uphold the concepts of innovation, quality, and service, continuously improve our technical level and product quality, provide customers with better CNC vertical lathes and more complete services, and jointly create a better future with customers.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN