What is a four - column hydraulic press?

The fuselage of the four-column universal hydraulic press adopts a three-beam and four-column structure. The hydraulic system adopts cartridge valve integrated control and an independent and reliable electrical control system. It has wide versatility and is suitable for the pressing processing and forming of various plastic materials, such as bending, stamping, deep drawing, etc.; it can also be used for powder molding, hot pressing molding, straightening, punching, hot forging, etc.

The three-beam and four-column hydraulic press is driven by hydraulic pressure and controls hydraulic actions through a cartridge valve integrated system. It has the advantages of reliable operation, long service life, small hydraulic impact, and reduced leakage points.

In addition, the independent electrical control system uses brand accessories to make the work more reliable, intuitive in action, and convenient for maintenance.

Through centralized control by buttons, two molding processes of fixed stroke and fixed pressure can be realized, and it has functions such as pressure maintaining delay. The working pressure of the slider, the stroke range of no-load express downward movement and slow working can all be adjusted according to process needs

If the hydraulic press is used for processes such as blanking and punching, a punching buffer device should be installed to eliminate or reduce the impact and noise at the moment when the material is broken.

In short, the three-beam and four-column hydraulic press is a hydraulic equipment with a simple structure, economic and practical, and convenient operation. It is widely used in the forming of various metal and non-metal materials. According to user needs, devices such as buffers and mobile workbenches can also be added to meet different production needs.

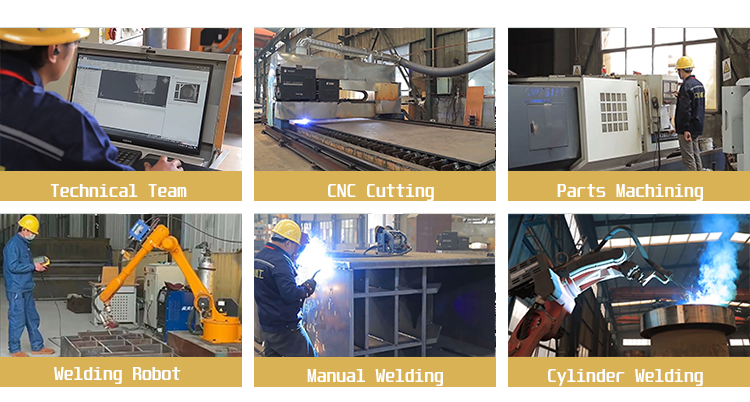

Nadun hydraulic press source factory supports customized hydraulic presses and can be equipped with molds and conduct on-site pressure tests.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN