They say once, macho machines were run by macho men. These men and women used their hands to form and shape metal into all sorts of functional products. It was labor-intensive work that took skill and patience. However, it is also a thing of the past, as these machines have been completely transformed by a special technology known as CNC VTL. They are smarter, speedier, and more accurate than ever before, which makes life easier for all of us.

What is CNC VTL Technology?

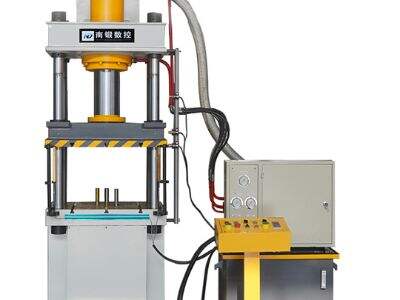

With CNC one expresses Computer Numerical Control; VTL, Vertical Turning Lathe. This technology has revolutionized the machinery running in factories. Previously, workers needed to manually adjust the machine settings. This was a slow process and could easily lead to errors. Now, utilizing CNC VTL technology, the workers can program the machines to perform precise tasks with just the push of a button. This allows them to focus on the more essential aspects of their job without having to manually adjust the timeline.

Inguagurating CNC VTL Technology- How it Stores Work-Workers Relationship

Not only is CNC VTL technology more user friendly for workers, it has revolutionized the stalwart heavy industry. CNC VTL has revolutionized the process of manufacturing by enabling automatic machine work. In other words, this means factories can produce more products in a lesser duration which assists in generating more revenue. This frees them to focus on more interesting and creative work, rather than just loading machines.

A Major Boost for Heavy Industries

Industries such as construction, mining, and airplane manufacturing heavily rely on CNC VTL technology. This technology allows for the development of machines that are safer and more robust for workers. It enhanced the quality of products which guarantees that the products customers buy last longer in end products. Not only does this reflect the benefit of keeping workers safe but it also creates ideas and designs that were not done in a physical world. Companies have a chance to innovate with CNC VTL and create more exciting and advanced new products.

How CNC VTL technology is Steadily growing

Since then, CNC VTL technology has evolved and developed continuously. Machines today can do many tasks: turning, shaping, milling, drilling. This versatility makes CNC VTL technology very popular in heavy industries. It is important for factories to produce accurate products at large scales in order to fulfill their customers' needs. Multitasking capabilities enable manufacturers to be more agile and receptive to market dynamics.

Importance of CNC VTL Technology

CNC VTL technology offers a huge advantage — precision. It reduces error on assembly since these machines can create parts which connect with each other exactly. This level of precision is essential when working heavy duty jobs as a small error could cause big problems or failures. The technology reduces human errors, allowing every piece to meet high-quality standards, keeping the products safer, and more reputable.

Slutsatser

This CNC VTL hydraulisk pressritning technology has completely transformed heavy industries & our approach to machining tasks. It has created new opportunities and enhanced the manner we work. CNC VTL technology is a very useful tool for factories due to its high precision, high efficiency, and versatility, Nadun brand!CNV VTL technology is the key technology for the armeenina factory worldwide. Looking Forward CNC VTL technology will play a pivotal role in future innovation and improvement of heavy-duty work and will continue to redefine our world for years to come. It will help work easier and lead to a wonderful future in the world of manufacturing.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN