Comment le fabricant de presses hydrauliques Nadun empaquette-t-il les presses hydrauliques ?

De nombreux clients se posent une question très importante : comment procédons-nous à l'emballage des presses hydrauliques ? C'est en effet une affaire importante.

En tant que fabricant professionnel de presses hydrauliques, nous attachons une grande importance à l'emballage des machines. Cela signifie que les machines sont livrées intactes dans les usines des clients.

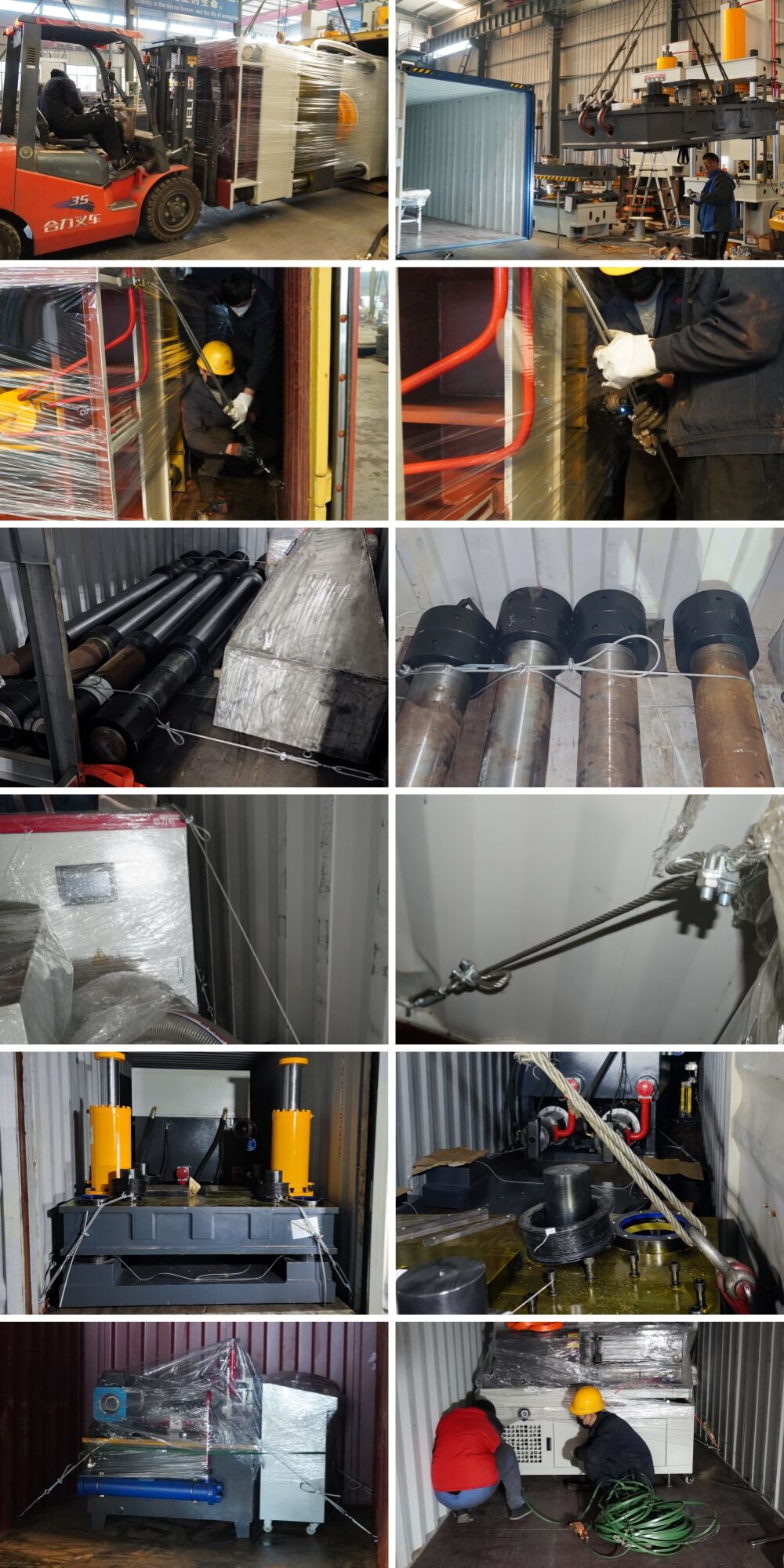

Généralement, pour certaines petites presses hydrauliques, nous enveloppons les machines de film plastique. Ce film plastique joue un rôle de protection de base. Il peut empêcher les machines d'être corrodes par la pluie, la poussière, l'humidité, etc., pendant le transport. Ensuite, nous utiliserons des attaches en fer et des caisses en bois pour l'emballage.

Pour les presses hydrauliques de grande taille, elles sont généralement transportées par conteneurs. Nous envelopperons également les machines de film plastique, installerons des crochets en fer sur les parties en contact avec le sol, puis les placerons dans les conteneurs selon un agencement raisonnable. Un agencement raisonnable peut garantir que l'espace à l'intérieur des conteneurs est utilisé efficacement et maintenir également le centre de gravité des machines stable pendant le transport. Enfin, nous utiliserons des câbles d'acier et des cordes pour fixer les machines. Les câbles d'acier et les cordes ont une résistance relativement élevée et peuvent supporter diverses forces inertielles pendant le transport, garantissant ainsi que les machines ne bougeront pas pendant le transport et n'occasionneront donc aucun dommage inutile.

Les positions de fixation sont également cruciales. En général, on choisit des parties structurelles relativement solides des presses hydrauliques pour la fixation, comme la base et les supports des machines. Et lors de la fixation, il faut prêter attention à la tension des câbles d'acier et des cordes. Ils ne doivent ni être trop lâches, ce qui entraînerait un mauvais effet de fixation, ni trop serrés au point de causer des dommages à la structure de la machine.

Si vous avez d'autres questions, faites-le nous savoir et nous vous donnerons des réponses dès que possible.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN