In the attempt to locate a wonderful CNC VTL machine, there are a couple essential features to consider. These aspects will certainly assist you in receiving much better results as well as expedite the machine functioning correctly according to your demands. Here are some highlighted features you should take a closer look.

Capacities of Precision Machining

The precise-cutting is the one of the most significant characteristics of a high-performance CNC VTL maker. It means that the machine can cut shapes and parts ultra-precise. This is important because it helps to ensure that your finished products are great and exactly what you need. For example, if you are printing a part for a toy or a piece of furniture, it must be fit perfectly. If the cuts aren’t exact, the pieces won’t fit well, and that will create problems.

Advanced Control Systems

The other prominent feature in these machines is their sophisticated control systems. They let you program the machine to do a lot of different things very well. But you can make a bunch of different parts without really doing anything else to the machine every time. So, if you have to change making a smaller section to a larger one, the training and the advanced control system intimidates the machine to quickly and in the most optimal way to adapt. This saves you time and helps keep your projects on target.

Efficient Tooling Options

Besides, a good CNC VTL machine should provide easy tools manipulations. The advantage is that this machine can easily switch between tool types, so moving between different jobs is a no-brainer — no time lost here! Suppose you are creating a model, and you need to use different tools to cut it, shape it, or drill it. As with efficient tooling options, you can swap tools fast, allowing for experimental work without long breaks. It allows you to do more in less time due to its efficiency.

Rigidity and Stability

The machine also has to be very sturdy and stable. It can withstand forces and vibrations during operation without losing its accuracy. If the machine jitters or shifts while it is cutting, it can make errors. This is why rigidity and stability are so important, because they help ensure that the final product that you have is high quality and that the exact product you want can be produced every time you use the machine.

Versatility in Operations

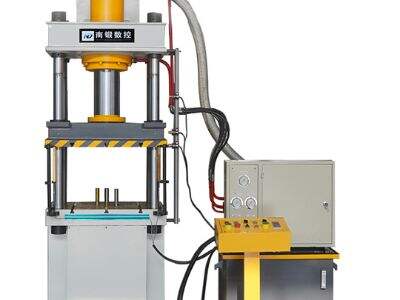

Finally, a seasoned CNC VTL 100 ton hydraulic press should be able to execute several duties. This means it’s capable of making simple cuts, but even more intricate shapes or designs. Versatility is key, it means you can tackle many projects and create many products without it requiring large numbers of different machines to complete similar jobs. For instance you might begin with a basic design and then decide to attempt to create something more intricate. Any good all-around machine should be able to do both without a hitch.

Finally, when buying face to face your exacting CNC VTL machine, it is important to consider the following key features. These are the characteristics, which ensure the good quality of machine and what you will be able to achieve with your results. Look for accuracy every time and also search machine with high technology control system, easy tooling, sturdy unit with multiple capability. Enhance your work with these features, take awesome results. And keep in mind that whenever you desire quality and performance you needed Nadun! This will assure you that you are getting a good choice for your projects.

EN

EN

AR

AR HR

HR CS

CS DA

DA NL

NL FI

FI FR

FR DE

DE EL

EL IT

IT JA

JA KO

KO NO

NO PL

PL PT

PT RO

RO RU

RU ES

ES SV

SV IW

IW ID

ID LV

LV LT

LT SR

SR SK

SK SL

SL UK

UK SQ

SQ ET

ET HU

HU TH

TH TR

TR FA

FA AF

AF MS

MS MK

MK KA

KA UR

UR BN

BN